by Tom Gaylord

Writing as B.B. Pelletier

BSA Meteor Mark I.

This report covers:

- Tune in a Tube

- Baseline the Meteor

- A second tune?

- Disassembly

- The compressor

- What did I find?

- The rest of the powerplant

- Offset transfer port

- The pivot point

- What’s next?

Ho ho, hi ho; inside the gun we go! Today’s report brings a lot of topics together on one stage.

Tune in a Tube

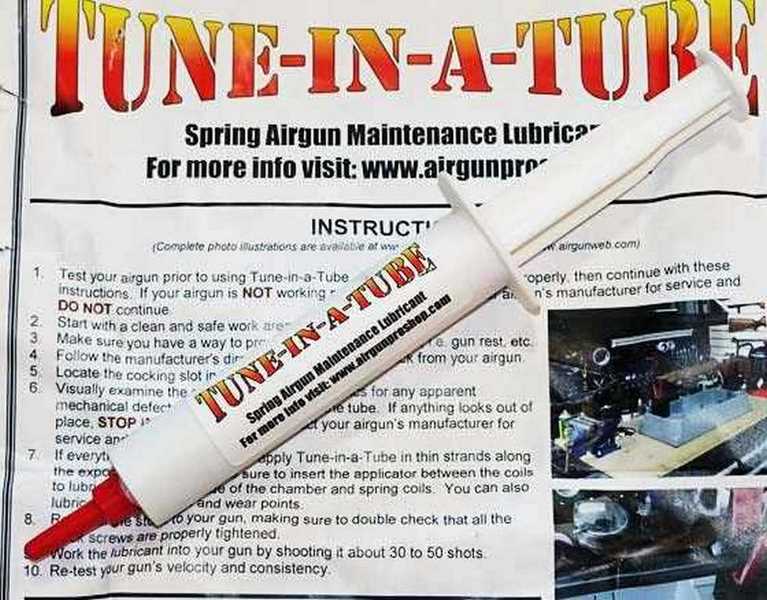

One reason I’m doing this is because reader RidgeRunner has been touting Tune in a Tube — or at least I think he’s one. This is getting confusing, so please bear with me. Tune in a Tube is a tube of viscous grease that comes in an applicator that makes it easy to squirt the grease into the spring gun powerplant. It’s a type of lube tune that is simple and supposewd to be very easy to do. I want to find out if it’s a product that does what it says, because if it is there are quite a few spring guns that could benefit from it.

Tune in a Tube looks simple and straightforward. Let’s hope it works!

Baseline the Meteor

Before I start working on the Meteor Mark 1 though, I thought it would be nice to establish a baseline of performance. I’ve done some of that already. In Part 2 of this report I tested the velocity. We know my rifle is very powerful for a Meteor and that it is also very buzzy. We don’t know anything about the accuracy yet, but as I have said many times, a tune does not affect the accuracy. Maybe it makes a gun more pleasant to shoot, but that’s all.

Today we’ll have a look at the parts of the Mark 1 powerplant, so we know the condition of the gun before I apply the grease. After we look at them I will assemble the gun again and apply Tune in a Tube — following the directions to the letter. I have to tell you that I have already read them and they are both simple and straightforward. The manufacturer doesn’t make any outlandish claims. So far, I am impressed by the product.

Then I will test the rifle after Tune in a Tube has been applied and give you a complete report. Except for accuracy. I won’t test that just yet.

A second tune?

After that I may tear the rifle apart again, clean it and do a more thorough tune; one like I did for the other Meteor in that 9-part series. I must tell you that this Mark 1 is quite a bit different than that Mark IV Super Meteor. We may be comparing apples to oranges. I’l know more after we look inside this gun today.

So that’s the plan. At least to this point. Let’s get started. Oh, and I will be using the new Sun Optics mainspring compressor that I reviewed for you yesterday to take the gun apart. If there is anything noteworthy there, I will mention it.

Disassembly

Before I started I read Part 2 of the Mark IV report. That was most helpful! It cut the time to do the job to a minimum and also saved some embarrassing missteps. The Mark IV and Mark I are different in some ways, but they come apart the same way.

The first step was to install the barreled action in the mainspring compressor. That took 5 minutes of adjustments. Then I was ready to begin.

I will cut to the chase and tell you to read that Part 2 I just linked to, because everything I did to this rifle is in that report. It took me 15 minutes to completely disassemble the rifle — including photography! With this new mainspring compressor the job is a snap, though I will now note some things about the compressor.

The compressor

It would have been better to have been able to use the new pusher block that has the pin, because my plastic pusher block walked around the headstock cup a lot. Also, I do lament the lack of a locating bump in the center of the tailstock to anchor the muzzle. Other than that, the new compressor works beautifully. The bridge bolts work a lot better than the leather belt I have to use with my older B-Square compressor. I’m going to look for some plastic cap nuts for my bolts.

What did I find?

Can you say “dry as a bone?” And rusty! I don’t think this rifle has ever been apart. The mainspring appears to be a stock one and it’s still very straight. There is some wear on the coils from rubbing over the years, but overall it’s in fine condition.

The spring is straight and dry. The trigger parts are dry and gritty.

I was surprised to see that the construction methods of the Mark 1 piston, i.e. folded metal that’s welded top and bottom, are identical to the Mark IV Super Meteor piston I worked on. That one was just broken in several places from a lot of abuse. This one seems to be fine and intact, but dirty and rusty!

This is the top of the piston, where the seal attaches. The spot-weld is visible.

The bottom of the piston may or may not be welded. If it is, it’s a very precise spot-weld. It may just be punched into shape.

The piston body is rusty!

The piston seal is leather and did have a little oil in it when I took the gun apart. It needs a lot more and I think I will oil the rifle through the transfer port after the rifle is assembled — just as I would if I never took it apart.

The piston seal is leather and looks good. It has a little oil, but needs more. A good cleaning is also in store — but after the Tune in a Tube.

The piston head is keyed into the top of the piston. And that’s not an optical illusion. The piston top is really out of round. The head is larger than the piston and that’s all that’s necessary to keep the seal centered in the compression chamber. This is mid-century economical engineering at its best!

The rest of the powerplant

The trigger parts are dirty and gritty and desperately need a cleaning. The mating sear surfaces seem to be shaped well and they seem to be properly case-hardened. I can tell that because they are not overly worn from use. I will NOT stone them! Case-hardening is too easy to remove with a stone — I don’t care how careful you are. Besides — I already told you this trigger is very nice. I will lubricate it with some moly grease, and I’ll also oil all the pivots.

Offset transfer port

I peeked inside the compression chamber to confirm that the walls are smooth, which they are. I also wanted to make sure there wasn’t any excessive dirt or smashed pellets that dropped through the air transfer port. People will sometimes load a .22-caliber pellet rifle with .177 pellets and you’ll find them at the end of the compression chamber, smashed into a wad. Thankfully the chamber was clean and clear. But what’s this? The air transfer port isn’t in the center of the chamber!

I guess I never paid attention to the Mark IV, but the transfer port has to be offset to align with the rear of the barrel. According to airgun tuners, that lowers the rifle’s power potential just a little. Nothing to do about it — I’m just pointing it out.

From the front the offset transfer port is obvious.

The pivot point

Remember that I had to repair the barrel pivot joint on my Mark IV? Well, this one seems fine, even though it’s the same construction. It’s dry, so I will moly it after this first test. For now I’ll just oil it.

The pivot point is plain and has no washers. It needs some moly, but it seems tight. Look at that detent that has popped out!

What’s next?

The rifle is assembled just as it was before. I will oil the pistol seal and the pivot point, but the next big thing will be applying the Tune in an Tube. The next report will be immediately following that, and I will give you velocities to compare as well as my impressions of the smoothness of the shot cycle.

I will definitely tear this rifle down a second time, to clean out all the rust. Yes, I left it all in the gun, except for a little that flaked off when I touched the parts. It felt like fingernails scratching a chalkboard, putting those dirty, rusty parts back in the gun, but how else am I going to test Tune in a Tube fairly?